Predict Mining Equipment Failures with AI

Teknoverse delivers AI-powered predictive maintenance software tailored for the mining industry. Our solutions help your operations reduce major component failures, improve asset reliability, and safely boost production, all while lowering maintenance costs.

By leveraging real-time data, intelligent algorithms, and predictive analytics, your team can anticipate issues before they occur, optimize maintenance schedules, and ensure equipment runs smoothly. With Teknoverse, mining companies gain smarter insights, safer operations, and higher productivity — all in a single, intelligent platform built for the demands of modern mining.

Book A Free Consultation!

Control Your Assets. Control Your Profits.

The profitability of your operation depends heavily on the availability and health of critical assets. Teknoverse combines AI-driven predictive maintenance with intelligent workflow tools to provide actionable insights for asset-intensive industries.

Our platform empowers your team to monitor equipment health, anticipate failures, optimize maintenance schedules, and maximize uptime — all while reducing costs and improving operational efficiency. With Teknoverse, you get the perfect fusion of smart technology and practical intelligence to keep your operations running safely and profitably.

Let's start a project together

We’ll contact you within a couple of hours to schedule a meeting to discuss your goals.

increased production and productivity

Let's start a project together

We’ll contact you within a couple of hours to schedule a meeting to discuss your goals.

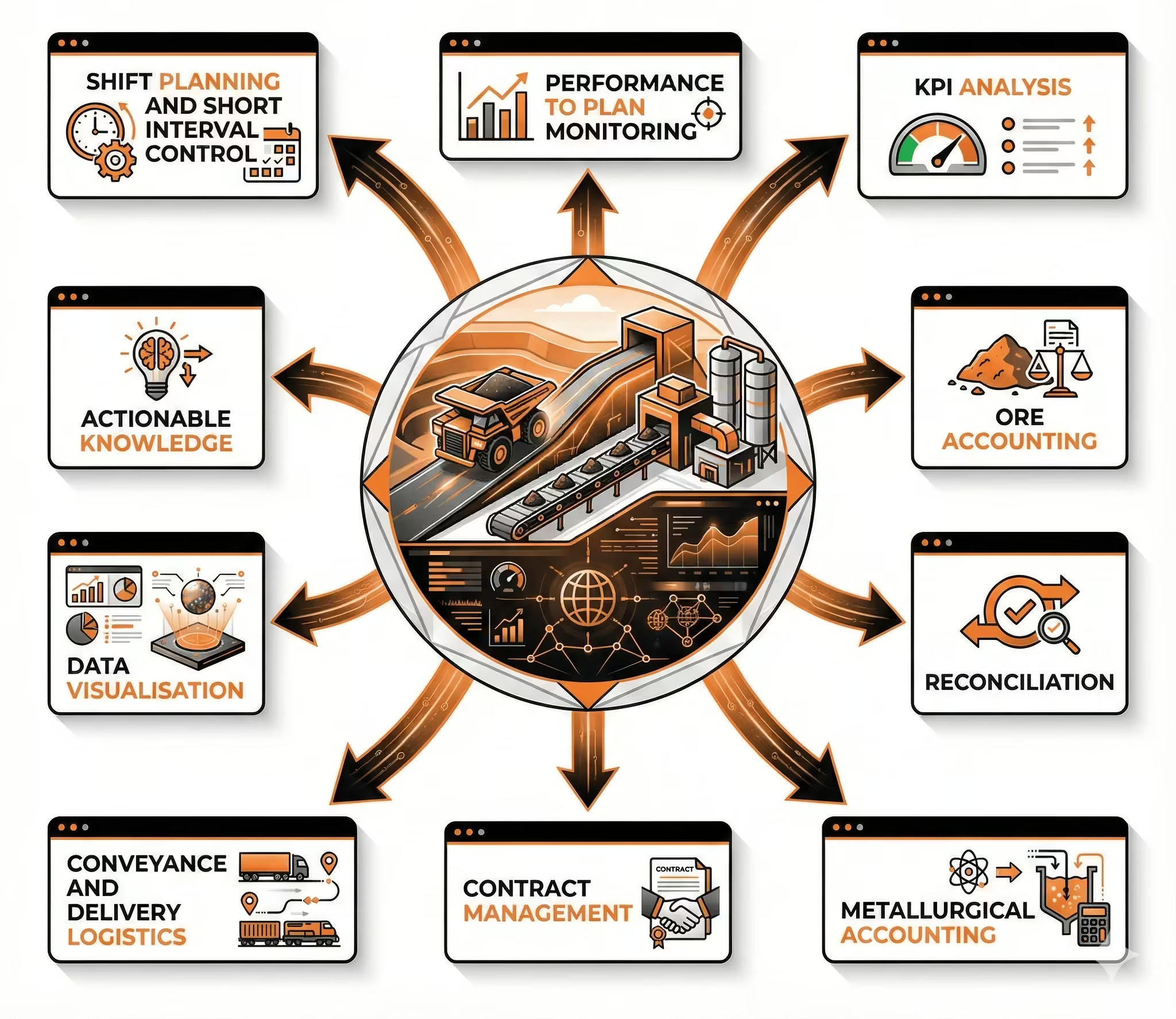

Set goals, collaborate with other crews, monitor progress, and remediate events that impact your team’s success.

Collect comprehensive metrics from your people and your equipment to measure how your business is performing against short-, medium- and long-term targets.

Use Key Performance Indicators (KPIs) across your entire enterprise to benchmark and monitor business performance to drive continuous improvement.

Monitor the quantity and quality of ore in conveyance and in stocks throughout the value chain.

Understand and improve the reliability of your resource/reserve estimations and production forecasts using powerful analytical and corrective reconciliation.

Track the flow of metal or product through production, ensuring you understand your operational efficiency and deliver accurate production and financial reports.

Ensure your customers’ and your business’ commercial and production goals and expectations are clearly defined and well-managed.

Plan the movement and delivery of your products to market to ensure visibility and accountability.

Provide operational and executive decision-makers with clear visualisations of KPIs and operating metrics through intuitive dashboards and powerful data analysis tools.

Deliver clear, concise operational and compliance reporting on demand or by subscription and critical-event notifications through SMS and email.

Enable effective decision-making through the efficient transformation of data into actionable knowledge.

Mining decision support and reporting

Achieve maximum efficiency and resource utilisation with our enterprise-wide decision support platform.

– Simplify processes for ore accounting, stocks management, and reconciliation.

– Boost productivity with streamlined shift planning and use of Short Interval Control (SIC) Tools.

– Consolidate production and performance data from multiple sources to gain actionable insights, including performance to plan (PTP) metrics and critical event notifications, for improved throughput and metals recovery.

Technology combined with our operational experience to supercharge your execution model

Exceed production goals

Implement systems and processes that empower you to maximise the potential of your mining enterprise.

Ensure accountability

Understand how effectively each aspect of your mining process is operating, and how you can optimise it.

Gain enterprise performance insights

Partner with internationally experienced geologists & engineers.

Let's start a project together

We’ll contact you within a couple of hours to schedule a meeting to discuss your goals.

Mining software solutions and supported areas

Operational planning

- Gathering the data about real performance directly from the machines and from mobile work order applications

- Visual planning using a multi-dimensional perspective

- Integration between plans and work orders in mobile apps – task assignments based on the plan

- Integration with laboratory – direct access to the attached analysis – mining operations are always drilling in the most cost-efficient area

Mining operations

- Mobile work orders for mine crew – access to task details, task performance checklists, task status reporting, time reporting

- Crew management (task assignment, task progress monitoring, reported time verification, holidays scheduling, replacements)

- Downtime reporting

- Incident reporting

- Precise production monitoring – from drilling to every enrichment stage Mobile app for the lab assistant to scan the drill-hole RFID and printout an analysis barcode

Automation / Technology

- Offline mode available for all mobile applications

- Industrial IoT (IIoT) connectivity – Integration between machines and ERP using OPC/UA, PLC, ABB 800xa / Siemens standards – real performance & maintenance statistics processing

- Computer Vision

- Augmented Reality for remote support for maintenance operators

Logistics

- Monitoring of the entire material / product flow at each delivery point by integrating IoT industry scales / RFID

- Mobile apps for truck drivers – GEO location monitoring – ability to track product stock at each location

- KPI dashboards to analyze truck utilization (ton*km) / monitor material loss in logistics

- Transportation planning based on operational plan and real amount of product on particular stages

Maintenance & Asset management

- Maintenance tasks planning – Integration with operational planning

- Mobile Work orders for maintenance (preventive & reactive) (incl. asset documentation management, inspection checklists off-line mode support)

- Tools management / Spare parts management

- Automatic gathering stats from machines to determine preventive tasks (i.e. based on the ton-km for trucks)

Safety & Compliance

- Compliance audits planning

- Audit execution on mobile devices with offline capabilities and checklists

- Integration of Health, Safety & Quality instructions in all work processes (applications)

- Safety incident management

- Safety certificates management/ access privileges checking

- Safety reporting & analysis

Awards & Recognitions

From aspiring to thriving, Teknoverse has earned recognition as a top iOS app development company, empowering tech-driven business growth through standout iPhone app solutions. We’re committed to pushing this promise further with innovative, future-ready strategies.

Frequently Asked Questions

Yes. Teknoverse integrates seamlessly with major ERPs, fleet management systems, telematics, and sensor platforms — ensuring your operations continue smoothly without workflow disruptions.

Our custom-built AI systems can handle predictive maintenance, equipment health monitoring, production optimization, operational safety insights, automated reporting, and more — depending on what your operation needs.

Absolutely. We tailor the solution to your site conditions, equipment type, and data availability to ensure stable, accurate, real-time performance even in tough mining environments.

Our AI models analyze your equipment's historical and real-time data. They detect early signs of component wear, unusual patterns, and performance anomalies — alerting your team before a failure occurs.

Yes — by reducing unexpected breakdowns, improving equipment availability, and automating manual reporting. The result is smoother operations and more consistent production output.

Every system we build uses enterprise-level security standards, encrypted data storage, and secure cloud or on-premise deployment (based on your preference), ensuring your mining data stays fully protected.